Modbus TCP: An introduction to the industrial protocol

Published

Basics of Modbus TCP

Modbus TCP is a fundamental communication protocol that plays a crucial role in the world of industrial automation. It was developed to facilitate the control and monitoring of devices in industrial environments by enabling efficient and reliable communication between different components. This protocol builds on the widely used TCP/IP network stack, which means that it can be seamlessly integrated into modern network infrastructures. Modbus TCP works according to the master-slave principle, whereby a central control device (master) transmits data from or to other devices (slaves). These devices can be sensors, actuators, controllers or other industrial components. Communication takes place via Ethernet networks, which ensures fast and reliable data transmission. Another important aspect of the Modbus TCP basics is the ease of implementation. The specifications are well documented and there are numerous libraries and tools available to facilitate development and integration. This makes Modbus TCP a popular choice for developers and engineers working in industrial automation. The basic building blocks of Modbus TCP include functions, addressing and data format. Functions define the type of communication, such as reading data from a slave device or writing data to a slave. Addressing makes it possible to address certain devices or registers in a simple way. The data format defines how the data is encoded and transmitted, ensuring interoperability between different devices. Overall, the basics of Modbus TCP provide a solid foundation for implementing and using this protocol in industrial automation. It is important to understand these basics to ensure efficient communication in complex industrial systems and to take full advantage of this proven protocol.

Advantages of Modbus TCP communication

The use of Modbus TCP in industrial automation offers a number of advantages that contribute to the efficiency, reliability and flexibility of industrial processes. One of the outstanding advantages of this protocol is its widespread acceptance and compatibility. Modbus TCP is an open protocol, which means that it is supported by a wide range of manufacturers and devices. This interoperability facilitates the integration of different components and makes it possible to extend or modify existing systems without causing incompatibility problems. Another significant advantage of Modbus TCP is its simplicity. The protocol is easy to understand and implement, which makes the development and maintenance of automation systems much easier. This leads to faster development cycles and lower costs for the implementation and maintenance of industrial networks. The efficiency of Modbus TCP is another plus point. It enables the fast and reliable transmission of data, which is crucial in many industrial applications. The low latency and low bandwidth usage make Modbus TCP ideal for real-time applications where the timely collection and control of data is essential. Security is an increasingly important aspect of industrial automation, and Modbus TCP offers advantages here too. Although it was not originally designed with comprehensive security features, developers and manufacturers have added security mechanisms such as encryption and authentication to protect communications. This allows companies to implement more secure industrial networks while benefiting from the proven advantages of Modbus TCP. Overall, the benefits of Modbus TCP communication are numerous, making it an attractive option for industrial automation. The high compatibility, simplicity, efficiency and security of this protocol help to increase the productivity and reliability of industrial processes worldwide.

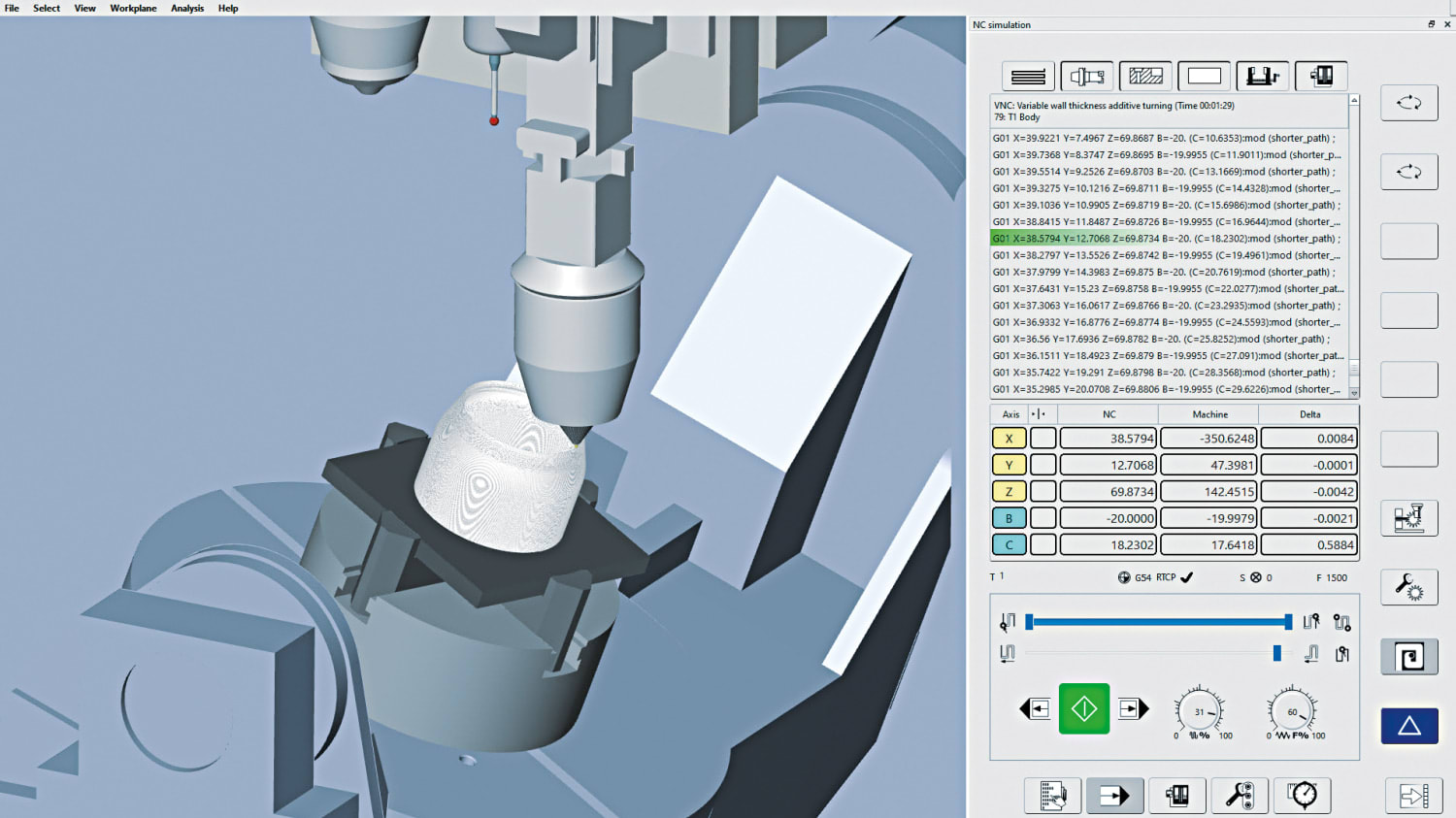

Implementation of Modbus TCP in the industry

The implementation of Modbus TCP in industry plays a crucial role in the modernization and improvement of automation processes in various sectors. Modbus TCP has established itself as one of the most widely used communication protocols in the industrial world, as it provides an efficient and reliable method of exchanging data between different devices and controllers. There are several key steps to consider when implementing Modbus TCP in an industrial environment. The first step is to select the appropriate hardware components. This includes identifying Modbus-enabled control systems, sensors, actuators and other devices to be integrated into the network. The selected components must be carefully integrated into the existing industrial network. This may require the configuration of IP addresses and other communication parameters to ensure that all components can communicate with each other. Software development is another crucial step in the implementation of Modbus TCP. This is where the specific communication requirements and functions are programmed. This includes sending and receiving Modbus messages, processing data and implementing control logic. Developers can use existing libraries and frameworks to speed up implementation and minimize errors. Seamless integration into existing process automation systems is also very important. This enables the centralized control and monitoring of systems and machines, which can significantly increase efficiency and productivity. Implementation often also requires the implementation of security measures to ensure data integrity and system availability. Once successfully implemented, Modbus TCP enables efficient monitoring and control of industrial processes. This helps to increase productivity, minimize downtime and reduce the total cost of ownership. The implementation of Modbus TCP in industry is therefore a decisive step towards improving competitiveness and adapting to the changing requirements of the modern manufacturing and automation industry.

Security aspects of Modbus TCP

Security is of paramount importance in modern industrial automation, and the use of Modbus TCP requires careful attention to various security aspects to ensure the integrity of processes and data. One of the main concerns when using Modbus TCP is the potential vulnerability to cyber-attacks. As the protocol is based on Ethernet and TCP/IP, it can be remotely accessible by attackers if not properly protected. To improve the security of Modbus TCP implementations, it is critical to establish robust authentication and access control mechanisms. This includes assigning user permissions and implementing passwords or other authentication methods to restrict access to Modbus devices and networks. The use of Virtual Private Networks (VPNs) or firewalls can help to block unwanted access and secure communications. Encryption also plays a crucial role in the security of Modbus TCP. Data transmissions should be encrypted to ensure that sensitive information cannot be intercepted or tampered with. The implementation of encryption protocols such as TLS (Transport Layer Security) or SSL (Secure Sockets Layer) can ensure the confidentiality and integrity of data. Regular security audits and checks are also important to identify and eliminate potential vulnerabilities. Updating device firmware and software is another important protection mechanism, as manufacturers often release security updates to address known vulnerabilities. Overall, security aspects of Modbus TCP are critical to ensure the reliability and integrity of industrial processes. Through careful planning, implementation and monitoring, companies can ensure that Modbus TCP can be used safely in their automation systems without the risk of security breaches.